Questions & Answers

A.: The full name of JEOL is Japanese Electron Optics Laboratory Company, Ltd. After decades of exploration and research by the world’s top scientific instrument manufacturers, they create the brand JEOL. Nowadays, JEOL products are widely applied in the fields of medicine, biology, biochemistry, agriculture, material science, metallurgy, chemical, petroleum, pharmaceuticals, semiconductor and electronics. Electron gun filament of JEOL is known to the Chinese businessmen. So far, there are more than 2000 users of JEOL in China. In China, electron gun filament of JEOL is used by a key laboratory sciences sector, research institutes, universities, medical institutions, government agencies and enterprises.JEOL electron gun filament is made of tungsten with a high-grade. Its features are high melting point and low coefficients of thermal expansion. This kind of tungsten is the best material for electron gun tungsten filament.

A.:The cathode of electron gun filament plays a decisive role on its life time. When the current intensity of the electron gun tungsten filament is more than 1 mA and the life time of electron gun tungsten filament can last for 100 hours longer.

A.: There are two main factors to affect the life time of electron gun tungsten filament. One is subjective reasons, heating emission requires a high temperature of the filament, The filament evaporation rate is proportional to the temperature index, the higher the temperature, the faster the evaporation rate of the filament. Therefore, under the condition of usage, user should try to ensure that the low temperature of electron gun tungsten filament, which is important for life time of the filament. Another is objective reasons: the surface of electron gun tungsten filament is easy to form a tungsten oxide layer due to the leakage of vacuum, and the evaporation rate of the tungsten oxide is N times higher than that of the elemental tungsten. If there exists oxygen inside the bulb and under high temperature conditions, the reaction between electron gun tungsten filament and oxygen will blow the filament. As a result of it, the life time of electron gun tungsten filament will be significantly shortened. In addition, the moisture content of air has a certain influence on life time of the electron gun tungsten filament.

A.:During the pressing process, if people select the thicker tungsten powder which would be difficult to suppress. It would result that the pressed compact higher needs a higher sintering temperature or more holding time in the next step sintering. What’s more, the thicker tungsten powder would waste much energy and time and has a great impact on the life time of the equipment. In the selection of the powder, in general, the thicker the tungsten powder is,the worse the compressibility is. And it would cause that users should choose a more large size of the mold cavity while filling it. A large powder needs for more pressure during the pressing. Except that, its compression is poor and it would directly reduce the density of the pressed compact. Therefore, when choosing the size of the powder, users should choose different sizes. The small size particles can fill the space leaving by large particles in the process of pressing to increase the density of compacts to avoid being cracked. In addition, the pressure of the pressing process also affects the qualified rate of the tungsten crucible compacts. Moreover, the qualified rate of the tungsten crucible compact is also affected by the hardness of the rubber sleeve, the greater the hardness, the more likely cause cracks.

A.:Because of the melting point of tungsten can reach 3600℃, tungsten crucible can be considered as the cord cage and widely applied to the furnace of sapphire products. And the temperature tungsten crucible is generally above 2000 ℃ while working. Especially for sapphire products furnace, characteristics of a high purity, high density, crack-free, precise size, smooth inner and outer walls of the tungsten crucible can greatly improves the success rate of seed of the growth of sapphire crystal. In addition, tungsten crucible also plays a key role in controlling the quality of crystal pulling and the life time of sapphire products.

A.:China is one of the richest tungsten resources storage countries in the world. Therefore, as deep processing product of tungsten, tungsten crucible industry has been continuously developed. Nowadays, China has a production capacity for some conventional tungsten crucible, but there still exist some problems for the high-tech products. For example, the manufacturing technique for complex shape of the tungsten crucible is relatively rare, but such products play an important role in the area of high technology. And for instance, quartz glass has been widely applied in laser technology, astronomy and sophisticated technology. With the rapid development of modern technology, as the core components of quartz glass, wolfram crucible has a wide range prospects for development. The next few years, the development direction of the tungsten crucible will be large-size, high-quality, low-cost characteristics of tungsten crucible.

A.:Atomic absorption spectroscopy (AAS) is a spectroanalytical procedure for the quantitative determination of chemical elements using the absorption of optical radiation (light) by free atoms in the gaseous state. Tungsten boat atomic absorption spectrometer is one of the most important types of AAS. This type of instrument can detect trace amounts, and has a high sensitivity, the accuracy of result is also very high. In addition, tungsten boat AAS has an advantage of a low power and it doesn’t need for any industrial electricity.

A.:Tungsten boat is widely used in electronics industry, such as kinescope, mirror making, toys, household appliances, mobile phones, electrical enclosure. It has good characteristics for electrical conductivity, thermal conductivity, high temperature resistance, wear resistance, corrosion resistance. In addition, wolfram boat has a high melting point, low saturated vapor pressure and stable chemical properties, so it has been widely used as source for resistive evaporation in vacuum evaporation coating industry. W-boat, as an essential part for vacuum coating equipment, the selection of tungsten boat determines the quality of the coating.

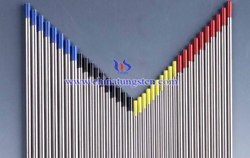

A.:Tungsten electrode is divided into pure tungsten electrode, thoriated tungsten electrode, lanthanum tungsten electrode, cerium tungsten electrode, zirconium tungsten electrode, yttrium tungsten electrode, silver tungsten electrode and composite tungsten electrode which is based on different materials. The main application is the welding alternating current for aluminum and magnesium. People can classify them on their color.

A.:Because tungsten electrodes have many types, people use different colos to distinguish them. Red is thorium tungsten electrode, gray is cerium tungsten electrode, yttrium tungsten electrode is blue, green is pure tungsten electrode, brown is zirconium tungsten electrode. Golden is lanthanum tungsten electrode and sky blue is lanthanum tungsten electrode.

A.:Tungsten electrode is one of the main source material for TIG welding. The world's total annual consumption of the tungsten electrode achieve 1600t, market demand is still growing as the development of economy. China's total output of tungsten electrode is about 3/4 of the world. China's annual output of the tungsten electrode has been growing steadily, and there was a sharp increase from 2005, it reached 1200t in 2009.

A.:The thoriated tungsten electrode has strong radioactivity. Inhalation or injection of α particle would be very dangerous. Because it has a strong destructive power to the body's internal organs, cells, tissues. When using this electrode, users should pay attention to ventilation.

A.:Lanthanated tungsten electrode contains lanthanum oxide that slightly soluble in water and easily to dissolve in acid, and then generate the corresponding salts. If it is placed in the air, it absorbs carbon dioxide and water of air, gradually become lanthanum carbonate. Burning lanthanum oxide and water will release a lot of heat. This type of electrode is mainly to improve the radioactive damage caused by thoriated tungsten electrode.

A.:Polishing is the process of creating a smooth and shiny surface by rubbing it or using a chemical action, leaving a surface with a significant specular reflection. In some materials (such as metals, glasses, black or transparent stones) polishing is also able to reduce diffuse reflection to minimal values. When an unpolished surface is magnified thousands of times, it usually looks like mountains and valleys.

A.:The whole name of TIG is Tungsten Inert Gas Welding. It is a kind of welding which use pure tungsten or rare earth tungsten alloy as an electrode, and the protective gas is inactive gas. It can be used in DC and AC and DC-AC dual current. Aluminum, magnesium and their alloys selected AC. TIG welding should be strictly in accordance with the instructions of device to ensure safety.