PA Alloy Probes

PA alloy probes are mainly applied to probing machine for chip testing by electrically contact to LED bonding pads and apply current/voltage to obtain output characteristics.

Applications

1.Suitable in the probe testing LED chips for obtaining opto-electronic output characteristics;

2.Suitable in the probe testing VCSEL, EELD, DFB chips for obtaining opto-electronic output characteristics.

3.Suitable in the probe testing photo-sensitive devices such as Photodiode (PD), Phototransistor (PTR), Schottky diode and Zener diode for obtaining opto-electronic output characteristics.

Main Specifications

Main Specifications |

||

Parameter |

Parameter |

Parameter |

Diameter |

0.5 mm (+/- 0.05 mm) |

Standard |

Length |

19.0 mm (+/- 0.05 mm) |

Customized |

Taping Angle |

6~13 degree |

Customized |

Tip Radius R |

2~100 um |

Customized |

Bending Degree |

90~130 degree |

Customized |

Product Specifications

(1) Straight type

Main Specifications |

||||

Length |

Diameter |

Taping angle |

Tip Radius |

Remark |

10.5 |

0.5 |

7 |

50 |

|

19 |

0.5 |

8 |

4 |

|

19 |

0.5 |

8 |

5 |

|

19 |

0.5 |

8 |

10 |

|

19 |

0.5 |

8 |

20 |

|

19 |

0.5 |

9 |

5 |

|

19 |

0.5 |

10 |

2 |

|

19 |

0.5 |

10 |

2 |

|

19 |

0.5 |

10 |

3 |

|

19 |

0.5 |

10 |

4 |

|

19 |

0.5 |

10 |

5 |

Tip careful handling |

19 |

0.5 |

10 |

6 |

|

19 |

0.5 |

10 |

6 |

High hardness |

12 |

0.5 |

10 |

6 |

|

13 |

0.5 |

10 |

6 |

High hardness |

19 |

0.5 |

10 |

9 |

|

19 |

0.5 |

10 |

10 |

|

19 |

0.5 |

10 |

12 |

|

19 |

0.5 |

10 |

15 |

|

19 |

0.5 |

10 |

20 |

|

19 |

0.5 |

10 |

20 |

Tip Brightening |

19 |

0.5 |

10 |

25 |

High hardness |

38 |

0.5 |

10 |

25 |

|

38 |

0.5 |

10 |

25 |

High hardness |

30 |

0.5 |

10 |

30 |

|

20 |

0.5 |

10 |

100 |

|

19 |

0.5 |

11 |

14 |

|

19 |

0.5 |

12 |

5 |

|

19 |

0.5 |

12 |

6 |

|

19 |

0.5 |

12 |

10 |

|

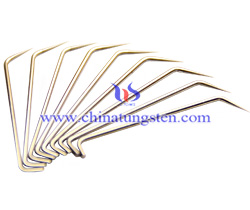

(2) Bending type

Main Specifications |

||||||

Length |

Diameter |

Bending angle (degree) |

Taping angle (degree) |

Tip Radius |

Height |

Remark |

20 |

0.5 |

120 |

6 |

5 |

4.0~4.5 |

|

19 |

0.5 |

120 |

6 |

6 |

4.0~4.5 |

High hardness |

19 |

0.5 |

120 |

6 |

6 |

3.6~3.9 |

High hardness |

20 |

0.5 |

120 |

6 |

6 |

4.0~4.5 |

High hardness |

23 |

0.5 |

120 |

6 |

6 |

5.9~6.1 |

|

23 |

0.5 |

150 |

6 |

6 |

3.6~3.9 |

|

31 |

0.5 |

120 |

6 |

6 |

3.6~3.9 |

High hardness |

19 |

0.5 |

120 |

7 |

1 |

3.0~3.2 |

|

19 |

0.5 |

120 |

7 |

2 |

3.0~3.2 |

|

19 |

0.5 |

112 |

7 |

5 |

4.0~4.5 |

|

19 |

0.5 |

120 |

7 |

6 |

3.0~3.2 |

|

19 |

0.5 |

120 |

7 |

6 |

3.2~3.5 |

|

19 |

0.5 |

110 |

7 |

6 |

3.0~3.2 |

|

19 |

0.5 |

125 |

7 |

6 |

3.0~3.5 |

Tip Coarsening |

15 |

0.5 |

120 |

7 |

6 |

3.0~3.2 |

Tip Atomization |

17.5 |

0.5 |

120 |

7 |

6 |

3.0~3.2 |

|

19 |

0.5 |

125 |

7 |

16 |

3.0~3.5 |

Tip Coarsening |

19 |

0.5 |

125 |

7 |

16 |

3.0~3.5 |

High hardness |

19 |

0.5 |

90 |

7 |

16 |

3.0~3.5 |

High hardness |

19 |

0.5 |

125 |

7 |

30 |

3.0~3.5 |

Tip Coarsening |

19 |

0.5 |

125 |

7 |

30 |

3.0~3.5 |

High hardness |

19 |

0.5 |

120 |

8 |

3 |

3.5~4.0 |

|

19 |

0.5 |

110 |

8 |

5 |

3.1~3.5 |

|

19 |

0.5 |

120 |

8 |

6 |

3.1~3.5 |

|

19 |

0.5 |

120 |

8 |

6 |

3.0~3.2 |

|

19 |

0.5 |

120 |

8 |

6 |

3.8~4.2 |

High hardness |

23 |

0.5 |

120 |

8 |

6 |

6.0~7.0 |

|

19 |

0.5 |

105 |

8 |

18 |

2.8~3.0 |

|

23 |

0.5 |

120 |

8 |

50 |

6.0~7.0 |

|

19 |

0.5 |

90 |

9 |

5 |

3.0~3.2 |

|

19 |

0.5 |

120 |

10 |

2 |

3.0~3.2 |

|

19 |

0.5 |

120 |

10 |

2 |

3.0~3.2 |

Tip careful handling |

19 |

0.5 |

120 |

10 |

2 |

3.0~3.2 |

High hardness |

19 |

0.5 |

120 |

10 |

3 |

3.0~3.2 |

|

19 |

0.5 |

120 |

10 |

3 |

3.0~3.2 |

High hardness |

19 |

0.5 |

110 |

10 |

3 |

3.2~3.5 |

|

19 |

0.5 |

120 |

10 |

4 |

3.0~3.2 |

|

19 |

0.5 |

120 |

10 |

6 |

3.0~3.2 |

Tip careful handling |

19 |

0.5 |

120 |

10 |

6 |

3.0~3.2 |

High hardness |

19 |

0.5 |

120 |

10 |

6 |

2.8~3.0 |

|

19 |

0.5 |

110 |

10 |

6 |

3.0~3.2 |

|

19 |

0.5 |

110 |

10 |

6 |

3.2~3.5 |

|

19 |

0.5 |

105 |

10 |

6 |

3.0~3.2 |

|

19 |

0.5 |

115 |

10 |

6 |

3.0~3.2 |

High hardness |

25.4 |

0.5 |

110 |

10 |

6 |

3.0~3.2 |

|

20 |

0.5 |

120 |

10 |

6 |

4.0~4.2 |

|

19 |

0.5 |

120 |

10 |

8 |

3.0~3.2 |

|

19 |

0.5 |

120 |

10 |

8 |

3.0~3.2 |

High hardness |

19 |

0.5 |

120 |

10 |

10 |

3.0~3.2 |

|

19 |

0.5 |

120 |

10 |

10 |

3.0~3.2 |

High hardness |

19 |

0.5 |

120 |

10 |

12 |

3.0~3.2 |

|

19 |

0.5 |

120 |

10 |

13 |

3.0~3.2 |

|

19 |

0.5 |

120 |

10 |

13 |

3.0~3.2 |

High hardness |

19 |

0.5 |

120 |

10 |

14 |

3.0~3.2 |

|

19 |

0.5 |

120 |

10 |

20 |

3.0~3.2 |

|

19 |

0.5 |

105 |

10 |

20 |

3.2~3.5 |

|

19 |

0.5 |

120 |

10 |

25 |

3.0~3.2 |

High hardness |

19 |

0.5 |

120 |

10 |

30 |

3.0~3.2 |

|

19 |

0.5 |

110 |

10 |

30 |

3.0~3.2 |

|

19 |

0.5 |

110 |

10 |

50 |

3.2~3.5 |

|

19 |

0.5 |

120 |

10 |

60 |

3.0~3.2 |

High hardness |

19 |

0.5 |

120 |

10 |

80 |

3.0~3.2 |

|

19 |

0.5 |

120 |

10 |

90 |

3.0~3.2 |

|

19 |

0.5 |

120 |

10 |

120 |

3.0~3.2 |

High hardness |

19 |

0.5 |

120 |

10 |

125 |

3.0~3.2 |

High hardness |

19 |

0.5 |

120 |

11 |

2 |

3.0~3.2 |

|

19 |

0.5 |

120 |

11 |

4 |

3.0~3.2 |

|

19 |

0.5 |

120 |

11 |

14 |

3.0~3.2 |

|

19 |

0.5 |

120 |

12 |

2 |

3.0~3.2 |

|

19 |

0.5 |

95 |

12 |

2 |

3.0~3.2 |

|

19 |

0.5 |

120 |

12 |

13 |

3.0~3.2 |

|

19 |

0.5 |

120 |

13 |

6 |

3.0~3.2 |

|

19 |

0.5 |

120 |

13 |

20 |

3.0~3.2 |

|

15 |

0.5 |

120 |

13 |

20 |

3.0~3.2 |

|

15 |

0.5 |

120 |

13 |

20 |

3.0~3.2 |

High hardness |

If there is any interest in tungsten products, please feel free to contact us through the following methods.

Email: sales@chinatungsten.com

Tel.: +86 592 512 9696/+86 592 512 9595

More info>>