Furnace Tungsten Components

In industrial manufacturing, high temperature furnaces are widely used for material heat treatment or high temperature heating processes. These furnaces usually adopt full-metal or hybrid zones with graphite or ceramic fiber insulation, and hot zones are made of tungsten, molybdenum, tantalum, niobium and their alloys.The industrial furnaces include high temperature vacuum furnaces, protective atmosphere furnaces, hot isostatic pressing furnaces (HIP), quartz melting furnaces, MOCVD substrate heaters, sapphire growth furnaces, etc. The applicable temperature ranges from 900℃ to 2800℃.

Tungsten is a unique substance in many ways: it has the highest melting point and lowest vapor pressure of all metals; high density, low contamination, high tensile strength, excellent corrosion resistance, high compression and elasticity modulus, high thermal creep resistance, excellent electrical and thermal conductivity, and a very important electron emission coefficient. Therefore, parts used in hot zones are mostly made of tungsten and its alloys.

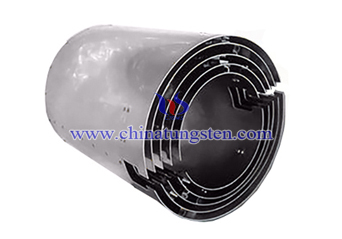

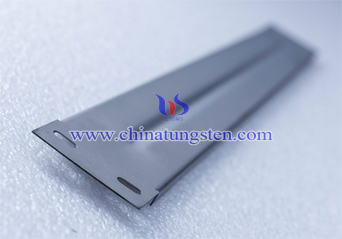

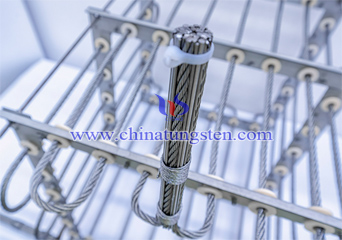

Furnace tungsten components includetungsten heater,tungsten heat shield,tungsten supporter,tungsten crucible,tungsten crucible cover,tungsten base plate,stranded tungsten wire,tungsten heating elements,tungsten mandrel shafts,tungsten plate,tungsten rod,tungsten tube,tungsten wire rope,tungsten machined die-plate, tungsten bolts, tungsten nuts and so on.

|

|

|

|

|

|

If there is any interest in tungsten products, please feel free to contact us through the following methods.

Email: sales@chinatungsten.com

Tel.: +86 592 512 9696/+86 592 512 9595

More info>>

Hot Zone Parts of Sapphire Growth

High Temperature Furnace Parts