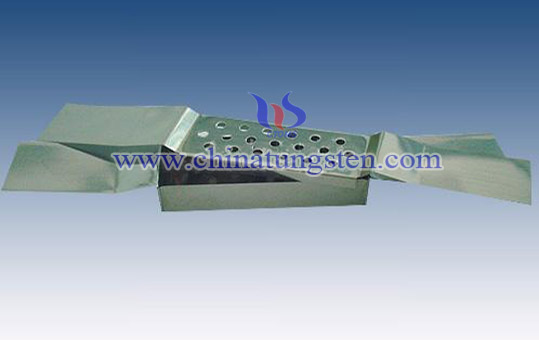

Evaporating Tungsten Boat

Introduction

Evaporating tungsten boat is also known as coating tungsten boat which is widely applied in vapor deposition industry. Due to its high melting point, low saturated vapor pressure and stable chemical properties, this type of W-boat has been widely used as resistance evaporation source in vacuum evaporation coating industry. while evaporating or coating materials, the melting point of the material cannot higher than the melting point of wolfram boat. Evaporating W-boat, as an essential part for vacuum coating equipment, the selection of wolfram boat determines the quality of the coating.

Manufacturing Process

Evaporating is a kind of process to put semi-film forming matter in vacuum for evaporation or sublimation, so that the film can be separated out on the surface of workpiece or substrate. Manufacturing process of evaporating wolfram boat is similar to the process of stamping tungsten boat, the difference is that the former has the holes for exhalation on the cover.

Application

Evaporating W-boat is widely used as resistance evaporation source. Its working methods is to make tungsten film into the shape of the boat firstly, then install it in two electrodes. Add materials in the center of tungsten boat, and then energize the electrodes slowly. After the current pass tungsten boat, the tungsten boat will give out the heating power. Low voltage and high current would transfer the heating power to the coating material, when quantity of heat of tungsten boat is higher than the melting point of the coating material, the material would obtain the sublimation or evaporation.

Advantages

The appearance of the evaporating W-boat is similar to the stamping W-boat, except that the surface of the former has holes which is conducive to sublimation and evaporation and improve coating efficiency.

Disadvantages

Evaporating tungsten boat needs to operate at high vacuum environment, therefore the demand of work environment is relatively strict.

Physical Properties

| Color | Melting point ℃ | Density g/cm3 | Purity % | Allowable Error(mm) |

| silvery white | 3407 | 19.35 | 99.95 | ±0.1 |