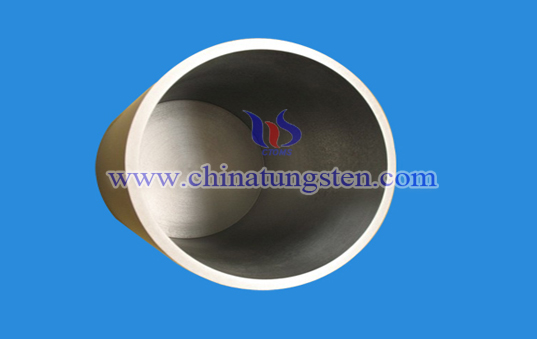

Tungsten Crucible

Introduction

As a kind of tungsten metal products, tungsten crucible has some very excellent properties, such as a high melting point, a high boiling point, a strong anti-friction resistance and the coefficient of thermal expansion is very small. Nowadays, tungsten crucible is widely used in rare earth smelting, quartz glass, electronic spraying and other industries. The purity of its tungsten is above 99.95% , its density is above 18.5g / cm3 and the maximum application temperature environment is 2400 ℃. According wolfram crucible manufacturing process, it can be divided into forging, sintering, stamping and spinning.

Sintering Tungsten Crucible

Sintering refers to a traditional process of processing the powdery raw materials into the dense bodies. People used this technology to produce ceramics, powder metallurgy, refractory materials, ultra-high-temperature materials before. The material sintering tungsten crucible is wolfram powder. Sintering tungsten crucible can be characterized by large-size production.

Forging Tungsten Crucible

Forging process is a manufacturing process which can make metal billet become plastic deformation by using localized compressive forces to obtain the forging parts with a mechanical energy, and a relatively shape and size. The raw material of forging tungsten crucible is a solid tungsten rod. After processing of the lathe system, then tungsten crucible can be produced. The advantage of the forging tungsten crucible is a high density. What’s more, it is not susceptible to be corroded with a longer life time.

Stamping Tungsten Crucible

Stamping type tungsten crucible is based on its plastic deformation. Since its manufacturing process is relatively simple and therefore stamping wolfram crucible is cheaper than other types. What's more, it is the most commonly used for inducturies. However, because of the characteristic of its processing work, wolfram crucible has an inherent problem: its wall is thin which is not conducive to long-term using and the number of re-use is less.

Spinning Tungsten Crucible

Fixed the flat or hollow blank on the spinning machine die, whilethe blank is rotating with the spindle, put pressure on billet with spinning roller to make the crucible have plastic deformation. Generally speaking, the size of this type of crucible is much smaller. Equipment and die are much simpler for foming spinning crucible.