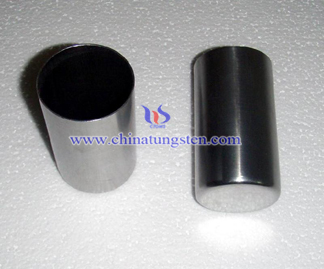

Sintering Tungsten Crucible

Introduction

Sintering refers to a traditional process of processing the powdery raw materials into the dense bodies. Generally, after preparing powder, the dense body can be obtained by sintering which is a polycrystalline material, the microstructure of it consists of the vitrella, vitreous composition and porosity. Sintering process directly affect grain size, pore size distribution of the shape of the vitrellathe of microstructure. Raw materials of sintering wolfram crucible is W-powder. Sintering wolfram crucible can be characterized by the large-size production.

Manufacturing Process

Today one of the main preparation method of industrial production of tungsten crucible is sintering. Firstly, install mould in accordance with the required dimensions, and then put wolfram powder which achieve the national standard in mould and seal it up. Next is to put it in an isostatic-press with a pressure of 180-250MPa to press. After that, put the press compact in high-temperature sintering furnace with 80-150 ℃ / h for holding 4-8 hours. Finally, the product is processed in accordance with the requirements. After processing, inspect the appearance, size, density and other quality of finished product.

Advantages

The size of sintering tungsten crucible is much bigger. Compared to stamping tungsten crucible, it has a longer life, more stable quality which is well received by many manufacturers. In china, the manufacturing process of large-sized sintering wolfram crucible has reached the international advanced level, therefore,the quality and productivity of this type are also at a high level.

Disadvantages

During the process, due to the change of materials in frequency sintering furnace would decrease, temperature difference between its inside and outside is relatively large, resulting that temperature will be greater different at different points when measure it . This makes it difficult to reflect the true temperature of tungsten crucible.

Physical Properties

| Purity % | Density g/ cm3 | Specification(mm) | Tolerance(mm) | Wall-Thickness(mm) | Surface Roughness(μm) | ||

| 99.95 | ≥18.50 | Diameter 10-500 | Height 10-750 | Diameter +/-5.0 | Height +/-5.0 | 8-20 | Ra=1.6 |