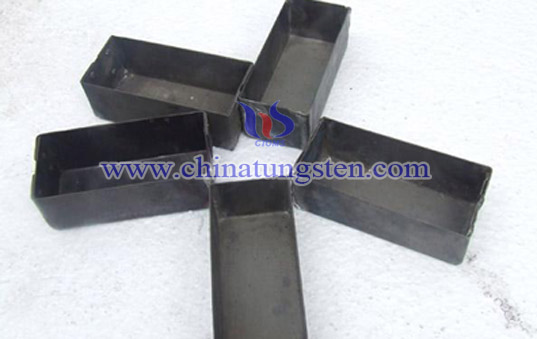

Sintering Tungsten Boat

Introduction

Sintering tungsten boat is mainly applied in the manufacturing process of wolfram powder by anhydrous wolframic acid. Sintering W-boat is an important carrier for making powder. Or load ammonium paratungstate (APT) in firing W-boat to make tungsten powder, the APT is white crystal, which include schistose and acicular, it is applied in the manufacturing process of tungsten metal powder by anhydrous wolframic acid or blue tungsten oxide.

Manufacturing Process

Sintering tungsten boat is mainly prepared by welding. Firstly, soldering the tungsten plates at a high temperature to melt the joint of boat, and finally cooling it to form the finished sintering W-boat. Because sintering process requires high temperature, the soldering wolfram boat by welding has a good thermostability.

Application

Sintering W-boat is mainly used in the preparation of tungsten powder. The powder or powder compact is put into firing W-boat, which was then heated below the temperature of melting point of the essential ingredients, and then cooling it into room temperature. Sintering is divided into three stages, namely the low temperature burn-in step, the medium temperature firing step and keeping warm in a high temperature. In the low-temperature burn-in step is mainly to volatilize the gas and moisture content which is adsorbed in wolfram boat. Anhydrous wolframic acid is a raw material of wolfram powder, and W-boat is the carrier of it.

Advantages

At the time of firing, sintering tungsten boat can remove a portion of the harmful impurities, such as sulfur, potassium, sodium and others. This type of W-boat reduces the adverse effects of harmful ingredients (water, oxygen, nitrogen) of the product under vacuum sintering. It is in favor of eliminating the adsorbed gas and the residual gas of the pores which can promote post-sintering shrinkage.

Disadvantages

During sintering, due to the high temperature, sintering stove would emit large amounts of waste heat.

Physical Properties

| Color | Melting point ℃ | Density g/cm3 | Purity % | Allowable Error(mm) |

| silvery white | 3407 | 19.35 | 99.95 | ±0.1 |