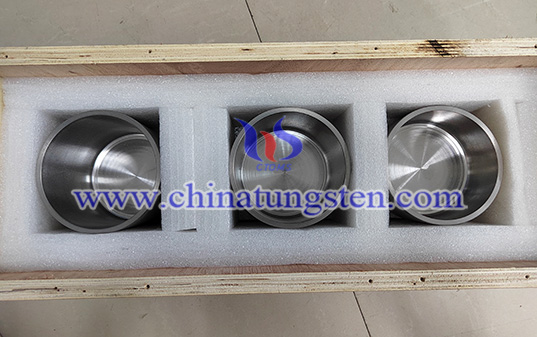

Plasma Sprayed Tungsten Crucible

Introduction

A plasma-sprayed tungsten crucible is a specialized type of tungsten crucible manufactured using plasma spraying technology. This process involves coating a base material with a high-purity tungsten layer, thereby achieving the high-temperature resistance and chemical stability of tungsten while reducing costs and enhancing manufacturing flexibility.

Features

1.High-Temperature Resistance – Tungsten has a melting point of 3410°C, making it suitable for extreme high-temperature environments.

2.Chemical Stability – Excellent corrosion resistance, ideal for molten metal handling and high-purity material processing.

3.Cost Optimization – The spraying process allows for the formation of a tungsten coating on a non-tungsten substrate, reducing overall tungsten consumption and lowering manufacturing costs.

4.Customizability – The coating can be applied to substrates of various shapes and sizes, making it suitable for specific industrial requirements.

Applications

1.Vacuum Evaporation Coating – Used as an evaporation source container to improve the purity of coating materials.

2.High-Temperature Melting – Suitable for melting special alloys or ultra-high-temperature materials.

3.Semiconductor Industry – Applied in high-temperature processes such as Chemical Vapor Deposition (CVD).

4.Scientific Research & Experiments – Used for studies requiring high-temperature resistance or plasma environment testing.

Currently, the application of plasma-sprayed tungsten crucibles remains limited, mainly due to challenges related to coating density and adhesion strength. However, in specific fields—particularly those requiring high-temperature endurance, corrosion resistance, and customized solutions—plasma spraying technology offers an efficient and cost-effective tungsten crucible solution.