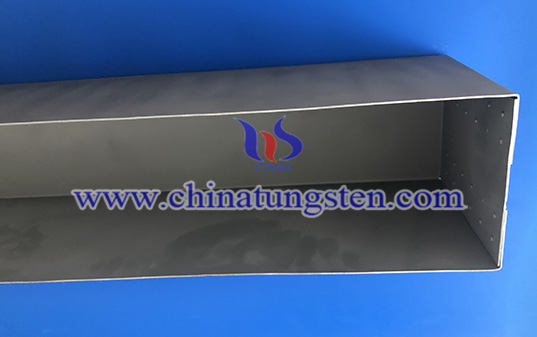

Riveted Tungsten Crucible

Introduction

A riveted tungsten crucible is a crucible made of tungsten and manufactured using a riveting process. It is widely used for melting and material processing in high-temperature environments. The term "riveted" refers to a mechanical joining method in which multiple tungsten plates or sheets are assembled into a single structure using rivets, rather than being manufactured through sintering, spinning, or welding.

Manufacturing Process

Riveting Process: Tungsten plates are fastened together with rivets to form the shape of the crucible.

Application Scenarios: This method is particularly suitable for producing large-sized or thin-walled crucibles, as processing a large tungsten piece into a single crucible may be challenging.

Why Use the Riveting Process?

Compared to sintering or welding, the riveted tungsten crucible offers the following advantages:

1.Flexibility – Allows for the production of larger crucibles, overcoming the limitations of single-piece tungsten processing.

2.Cost-Effectiveness – For small-batch production or customized requirements, the riveting process may be more economical.

3.Customizability – The crucible's shape and size can be adjusted based on specific applications.

Potential Drawbacks

1.Rivet Joint Strength – At high temperatures, the riveted points may be the weak spots, requiring high-quality craftsmanship to ensure durability.

2.Sealing Performance – Compared to sintered or welded crucibles, the riveted structure may have slightly lower sealing properties.

Practical Applications

Riveted tungsten crucibles are widely used in the following fields:

1.Sapphire Crystal Growth – Used for melting aluminum oxide (Al₂O₃) in high-temperature furnaces, ensuring the controlled growth of high-quality single crystals.

2.Rare Earth Metal Smelting – Applied in the melting of high-melting-point metals such as tungsten, molybdenum, and tantalum.

3.High-Temperature & Vacuum Furnaces – Serves as a container or lining that withstands extreme temperatures above 2000°C and vacuum conditions.