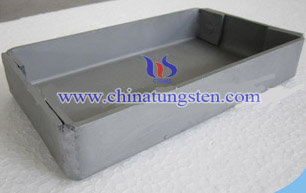

Welding Tungsten Boat

Introduction

Welding tungsten boat is also called heating tungsten boat, which is made of tungsten plates through welding in a high temperature. This type of wolfram boat have pores for evaporating on each side which are very dense. Holes of the bottom of the boat are more scattered. It has a very high thermostability that the temperature is 2000℃. Since that this type of W-boat is welded by two or more tungsten plates, its size is large.

Manufacturing Process

Welding is a fabrication or sculptural process that joins materials, usually metals or thermoplastics, by causing fusion, which is distinct from lower temperature metal-joining techniques such as brazing and soldering, which do not melt the base metal. In order to improve the quality of welding wolfram boat, users can use argon, carbon dioxide and other gases to avoid atmosphere so that it can protect the arc and rate of furnace hearth while welding. Finally, a boat shape is formed by welding.

Advantages

Its size is relatively large, so it can be used for large-scale evaporation device or a large number of material evaporation. Compared to riveting tungsten boat, welding W-boat can save material of 10% -20%, and it doesn't need to scribing, drilling, assembling, and other complex processes.

Disadvantages

Since welding W-boat is made of two or more plates, which cannot be made on one time, so the preparation time will be longer.

Physical Properties

| Color | Melting point ℃ | Density g/cm3 | Purity % | Allowable Error(mm) |

| silvery white | 3407 | 19.35 | 99.95 | ±0.1 |