Tungsten Heat Shield

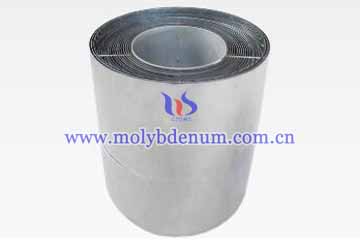

Tungsten plates have high density and high surface finish after high temperature hot rolling. Working in a vacuum environment, they have excellent thermal energy emission performance and can withstand high temperature for a long time without deformation and with very little volatilization. In addition, they have high temperature deformation resistance and high vapor pressure. Therefore, these metal plates are usually used as heat shields closest to the heating element in the core high temperature zone of the high temperature furnace.

The sapphire crystal growth process has high requirements on temperature stability and thermal field environment. The thermal insulation system controls the crystal growth environment. The uniformity of the hot zone will greatly affect the crystal growth quality, and the thermal insulation effect determines the power of the equipment. The correct hot zone structure and heating capacity can ensure a uniform temperature in the furnace, while greatly reducing heat loss. Therefore, tungsten heat shields with high melting point, high temperature stability and less pollution have been widely used in sapphire crystal growth furnaces.

Tungsten Heat Shield Specification

Thickness(mm) |

Width(mm) |

Length(mm) |

0.05~50 |

50~500 |

100~1500 |

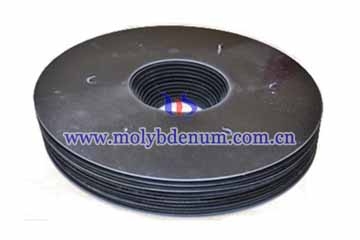

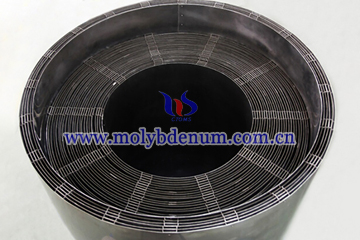

Types of Heat Shields

1,Metal reflective heat shield

2,Interlayer heat shield

3,Graphite felt heat shield

|

|

|

|

If there is any interest in tungsten products, please feel free to contact us through the following methods.

Email: sales@chinatungsten.com

Tel.: +86 592 512 9696/+86 592 512 9595

More info>>

Hot Zone Parts of Sapphire Growth