Tungsten Heating Elements

Tungsten heating elements are mainly used in various industrial high temperature furnaces. When current flows through the heating conductor, heat is generated. This resistance heating will generate high temperature in the high temperature furnace, so the material of the heating element must be resistant to high temperature and high melting point. Our tungsten, molybdenum and alloy components are made for this purpose. We can supply heating elements for a variety of high temperature furnaces depending on your applications.

By combining different structures and materials for the heating elements, we are able to achieve low surface loads and uniform temperature distribution. This ensures that the heating element can reliably withstand high temperatures even during prolonged operation.

Advantages of tungsten and molybdenum heating elements:

Tungsten and molybdenum metals are refractory metals that do not soften even at extremely high temperatures due to their high melting point. Compared to steel, refractory metals have a lower coefficient of thermal expansion and higher thermal conductivity. High radiation output, high temperature resistance, low heat capacity, low thermal expansion, low vapor pressure and excellent corrosion resistance are the main advantages of tungsten and molybdenum heating elements.

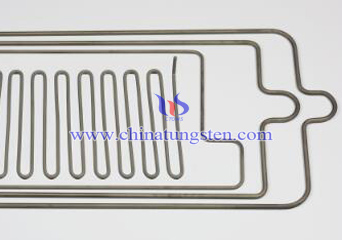

Refractory metal heating elements include sheets, rods, twisted wires, stranded wires, and wire mesh heaters.

|

|

If there is any interest in tungsten products, please feel free to contact us through the following methods.

Email: sales@chinatungsten.com

Tel.: +86 592 512 9696/+86 592 512 9595

More info>>

Hot Zone Parts of Sapphire Growth