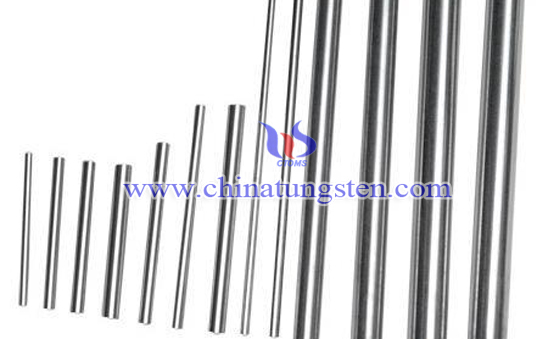

Forged Tungsten Rod

Introduction

Because of the high density, high hardness, high temperature, thermal conductivity and good conductivity and other characteristics, forged tungsten rod is widely used in aviation, aerospace, military, metallurgy, building materials and other fields, but also for the production of rocket engine Throat ray tube target material, armor-piercing bullet, molten salt electrolysis of rare earth electrodes, glass furnace electrodes. But the biggest drawback of wolfram is the poor room temperature ductility, so it is difficult to process it. Conventional production is to use powder-pressure and sintering process, the final products are low-density, low intensity, poor plasticity, and the application range is very restricted. Using forging method can produce smaller diameter tungsten rod, and the current technology is relatively mature with stable product performance, it can also produce large-size tungsten rod.

Forging

Forging is a manufacturing process involving the shaping of metal using localized compressive forces. The blows are delivered with a hammer (often a power hammer) or a die. Forging is often classified according to the temperature at which it is performed: cold forging (a type of cold working), warm forging, or hot forging (a type of hot working). Today, forging is a major worldwide industry. Forging can produce a piece that is stronger than an equivalent cast or machined part. the hardness and density of forging tungsten rod would be greatly improve after forging process. But if average forging ratio is too big, tungsten rod would has cracks and other defects. Under the temperature of 1450℃, the average forging ration should be lower than 32%.

Applications

Forging tungsten rod is mainly used for manufacturing of electric light and electric vacuum parts, high temperature heater and high temperature structure parts, electrical contact and electrode of rare earth.