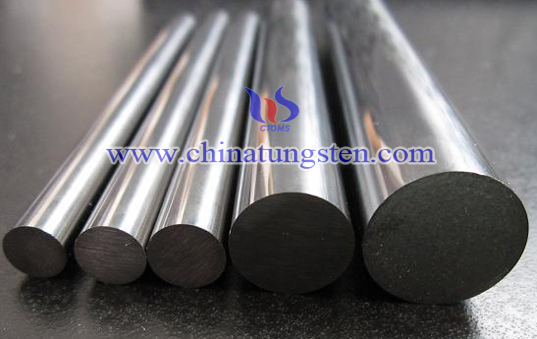

Ground Tungsten Rod

Introduction

Tungsten rod is made by sintering, incipient fusion, forging. Surface can be divided into smooth the surface by lathe, ground surface, black surface. Ground tungsten rod surface exhibits metallic luster without any obvious oxidation. Surface should be uniformity, it cannot have delamination, cracks, burrs and longitudinal surface cracks and other defects. Ground tungsten rod can be used in aviation, aerospace, electric vacuum, electric light, rare earth smelting and glass melting and so on.

Ground

Ground process is to use a rotating special sticky abrasive grinding wheel (or ribbon) to the cutting surface of metal parts. Ground surface can remove burrs, rust, scratches, weld, weld, trachoma, and other macro-scale defects of parts to improve the flatness and plating quality of parts. Ground process is suitable for all metals and some non-metallic materials. Tungsten rod surface after ground process would will be smoother without any cracks.

Applications

Due to some special properties, such as low thermal expansion and high thermal conductivity, sufficient anti-resistance, high modulus of elasticity, ground tungsten rod is widely used in various fields, mainly for the rare earth industry as a tungsten cathode, the high temperature heat generator and electric light. It can also used in support line, lead-in wire, printer pin, various electrodes and quartz furnace, filament, high-speed tool, car auto products, sputtering targets.

Physical Property

| Density: | Melting Point (Liquid) | Conductivity | Hardness |

| ≥19.1g/cm3 | 3422℃ | 30% IACS Min | 69HRA Min |

Parameter Declaration

| W | ≥99.95% | Color | Silvery White |

| Applications | Argon arc welding rod, electronics, precision instrument accessories | Industry: | Electronics |

| Model: | W1 | Specifications: | 10*100/5*100/6*100 |

| Packing: | wooden case, carton | Supplier | Chinatugnten Online (Xiamen) Manu. & Sales Corp. |