Tungsten Electrode

Introduction

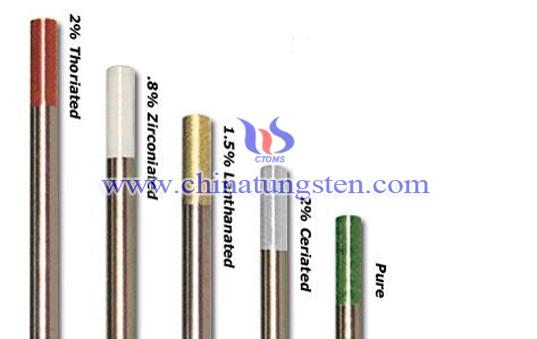

Tungsten electrode is divided into pure tungsten electrode, thoriated tungsten electrode, lanthanum tungsten electrode, cerium tungsten electrode, zirconium tungsten electrode, yttrium tungsten electrode, silver tungsten electrode and composite tungsten electrode which is based on different materials. The main application is the welding alternating current for aluminum and magnesium. People can classify them on their color.

Pure Tungsten Electrode

Pure tungsten electrode is the first electrode for arc welding, but in DC welding conditions, it is difficult to arc or the maintenance is instability. In order to improve the situation, it can be added rare earth oxides, the effect is significantly improved. In addition, pure tungsten electrode can only be applied as a welding electrode in AC.

Thoriated Tungsten Electrode

Thoriated tungsten electrode was the first one of the rare earth tungsten electrode, which is applied in DC negative electrode or carbon, stainless steel, nickel alloy, titanium alloys and other positive electrodes. They have a good operating performance, even if in the overload current, it can keep a good operation.

Lanthanated Tungsten Electrode

Lanthanum tungsten electrode has good performance of welding, so it enjoys a great popular by European countries. Its conductive property is the closest one with 2% thorium tungsten electrode. It has the characteristics of high durable current and the lowest burn out rate. After introducing to the market, it has gained the full recognition by the customers around the world with good prospects for development.

Cerium Tungsten Electrode

Cerium tungsten electrode is a kind of wolfram electrode which is added rare earth cerium oxide in wolfram base though powder metallurgy and rolling processes. It is first production of non-radioactive tungsten electrode products in China. The product is characterized with excellent arc performance and small dimensional arc current in the low current condition.

Zirconiated Tungsten Electrode

Pure tungsten electrode will often melt itself to contaminate at high load welding, in order to solve this problem, researchers developed a zirconium tungsten electrode. The biggest feature of zirconium wolfram electrode is that the ends of the electrodes can be maintained round shape and reduce tungstenizing phenomenon, and has good corrosion resistance even under high load.

Yttrium Tungsten Electrode

Yttrium tungsten electrode mainly contains tungsten and yttrium element. It has good compressive strength, and the main applications are military industry and aerospace industry. When welding, the arc beam is slightness, compressed degree is large.

Silver Tungsten Electrode

Silver tungsten material has good welding performance and corrosion resistance, and therefore it is widely applied in industrial and domestic circuit breaker. Various types of silver tungsten provide silver and wolfram with higher conductivity. Silver tungsten electrode is widely used in aerospace, aviation, electronics, electric power, metallurgy, machinery, sports equipment and other industries.

Composite Tungsten Electrode

Composite tungsten electrode is added two rare earth oxide or more, various additives complement insufficiency of each other, making its welding performance more superior. Composite rare earth tungsten electrode products have technical and economic superiority and strong market competitiveness.