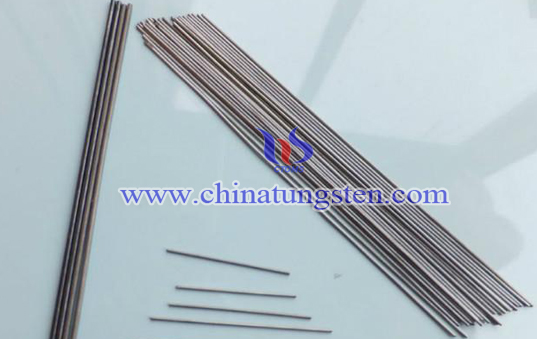

Polished Tungsten Rod

Introduction

Polished tungsten rod refers to the use the fuction of mechanical, chemical or electrochemical, thereby reducing the surface roughness of the tungsten rods, obtain more smooth way tungsten rod surface. Obviously, this type of tungsten rod has a high quality surface brightness and flatness.

Polishing

Polishing is the process of creating a smooth and shiny surface by rubbing it or using a chemical action, leaving a surface with a significant specular reflection. In some materials (such as metals, glasses, black or transparent stones) polishing is also able to reduce diffuse reflection to minimal values. When an unpolished surface is magnified thousands of times, it usually looks like mountains and valleys.

Differences between Ground and Polishing

There is no different between ground and polishing process basically. In the industry, ground process is the basic of polishing. Ground process is primarily for subsequent plating or coating formation processes. It can be said that polishing is the further optimization and upgrading of ground process. Polishing is to make the surface gloss. Polishing can make workpiece surface more smooth. The workpiece by grinding machine is more rough, but the polishing workpiece would be better.

Applications

Polishing tungsten rod is mainly used in glass melting, high-temperature furnace heating, welding electrodes, filament, X-37B weapons.