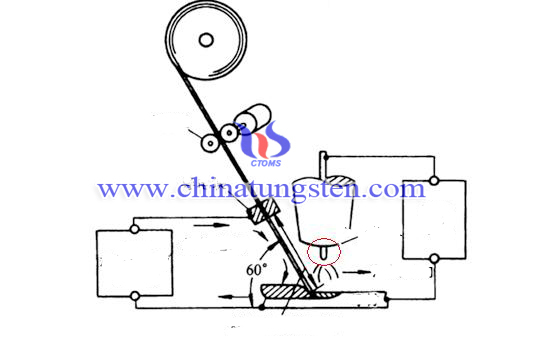

TIG Welding

Introduction

The whole name of TIG is Tungsten Inert Gas Welding. It is a kind of welding which use pure tungsten or rare earth tungsten alloy as an electrode, and the protective gas is inactive gas.

Selection of Welding Electrode

Selection of tungsten electrodes of TIG is wide, such as pure tungsten electrodes, thorium tungsten electrodes, cerium tungsten electrode, lanthanum tungsten electrode, yttrium tungsten electrode, composite electrode (Triad electrode). Conventional diameter containing Ø1.6mm, Ø2.4mm and Ø3.2mm, but the length is 150mm or 175 mm. Its international standard is ISO6848. The function of tungsten electrode is to conduct current, arc ignition and maintain the normal combustion, thus requiring a larger tungsten available current, high melting point, less wear and tear, and other good features.

Welding Object

Welding object of TIG welding can be stainless steel, nonferrous metals and alloys, less than 3mm thin pieces. This way is suitable for all-position welding.

Equiptment of TIG Welding

1) It can be used in DC and AC and DC-AC dual current. Aluminum, magnesium and their alloys selected AC.

2) Torch. There are two kinds of it: air-cooled and water-cooled. Component parts including the gun, nozzle, electrode holder, cable, argon inlet tube, water pipes and switches and buttons.

3) Gas supply system

4) Cooling system

5) Tungsten

TIG welding should be strictly in accordance with the instructions of device to ensure safety.