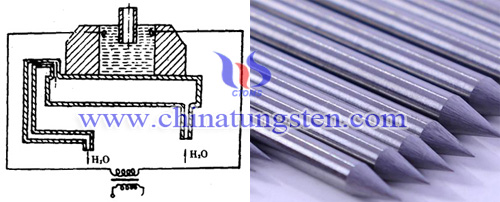

Barium Tungsten Electrode Manufacturing Process

Maunfacturing process of barium tungsten electrode is impregnated method. The advantages of this method of making an electrode include: good emission properties, high current density, smooth appearance and long product life time. But the process is more complex and more difficult. To prepare impregnated Ba-W electrode must have two elements: tungsten cavernous and emissive material.

Tungsten Cavernous:

1. The melting point should be high, evaporation rate is small, the vapor pressure is low, higher mechanical strength, expansion coefficient is small, the resistivity is large.

2. The formula: W (250 mesh/cm²) 97g, paraffin 3g.

3. Function: lubricating, bonding, holding hole. Gasoline (aviation gasoline) 30 ~ 40cc + glycerol.

4. Process:

(1) Poure gasoline → paraffin (to make it melt) is poured into → tungsten powder (about 180℃) → rapid stirring, until gasoline cannot be smelt → sieving → 75 ~ 80 mesh/cm² → pressing → box (or the shape of direct requests) pressure 2T/cm².

(2) Low-temperature sintering (deparaffinized, to maintain a certain hardness, slow heating at 600℃ prior to 100 ~ 150℃/h. When it reaches 600 ~ 1400℃, 200℃/h (1 hour incubation) directly mold to burn 1700℃.

(3) Sintering temperature at 2000℃ (about half an hour) emitting material in vacuum resistance furnace.

Emissive Material:

1. Barium Aluminate:

Melting point is 1600℃ (impregnation temperature 1700℃ ~ 1750℃), put it in oven → grinding → pressed into blocks → add the Al2O3 to the molybdenum boat (BaCO3·CaCO3 decomposition), 700 ~ 800℃ incubated for 1 hour, 800 ~ 900℃ for 1 hour, 1400℃ for 2 hours → finished product.

2. Barium Zirconate: Mix powders and distilled or deionized water to form a spherical shape, and then put it in furnace for sintering, grinding, mesh screening to 80~75 mesh/cm².

If there is any interest in tungsten electrode, please feel free to contact us through the following methods.

Email: sales@chinatungsten.com

Tel.: +86 592 512 9696/+86 592 512 9595

More info>>