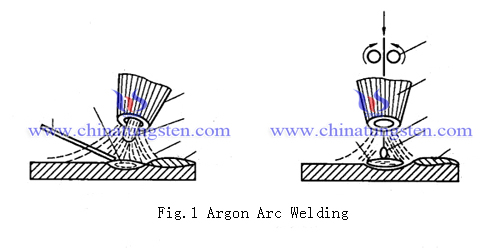

Tungsten Electrode Application - Argon Arc Welding

Argon is used as a shielding gas to protect weld and tungsten. Argon arc welding is to introduce argon gas in electric-arc welding, then air is isolated from the welding area to prevent the welding area from being oxidized. It is a general designation of tungsten argon arc welding and MIG argon welding. The former is to use cerium thorium tungsten or tungsten rods as electrodes, the latter is to use solder wire to make a consumable electrode.

Characteristics:

(1).Metal and its alloy can be welde which have very active chemical properties. Inert gas argon or helium would not react with active chemical properties such as aluminum, titanium, magnesium, copper, nickel and its alloys even at high temperatures.

(2).Soldering seam obtained by this method has high metal purity, less gas and metal inclusions and less welding defects.

(3).Welding thin pieces, small pieces.

(4).Welding productivity is low.

The welding current of the tungsten electrode argon arc welding is limited by the capacity of the tungsten current carrying capacity, the arc power is small, the arc penetration is small, the penetration depth and the welding speed is low.

If there is any interest in tungsten electrode, please feel free to contact us through the following methods.

Email: sales@chinatungsten.com

Tel.: +86 592 512 9696/+86 592 512 9595

More info>>