Tungsten Electrode Application - Aluminum Alloy Welding

Tungsten electrode application application is aluminum and aluminum alloy welding. Aluminum and its alloys can be joined by more methods than any other metal, but aluminum has several chemical and physical properties that need to be understood when using the various joining processes. The specific properties that affect welding are its oxide characteristics, its thermal, electrical, and nonmagnetic characteristics, lack of color change when heated, and wide range of mechanical properties and melting temperatures that result from alloying with other metals.

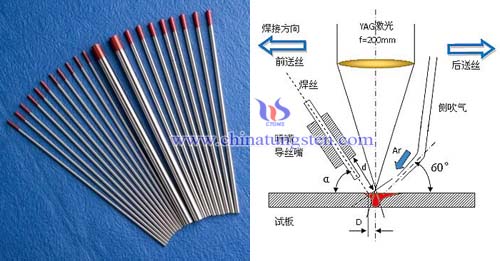

Almost all kinds of welding methods can be used for aluminum and aluminum alloys, but aluminum and aluminum alloys have different adaptability to a variety of welding methods, various welding methods have their respective applications. Gas welding and arc welding methods's devices are simple and easy to be operated. Aluminum and aluminum alloy sheet can be welded by tungsten electrode AC pulse welding. Aluminum and aluminum alloy plate can use tungsten arc welding, argon-helium mixed gas tungsten arc welding, MIG welding, pulsed MIG welding.

Aluminum and Aluminum Alloys TIG Welding Parameters:

| Weldment Thickness mm |

Wire Diameter mm |

Tungsten Electrode Diameter mm |

Preheat Temperature ℃ |

Welding Current A |

Argon Flow Rates L/min |

Nozzle aperture mm |

Layer Number (positive / negative) |

Note |

| 1 | 1.6 | 2 | — | 40~60 | 7~9 | 8 | Positive1 | Flanged Edge Welding |

| 1.5 | 1.6~2.0 | 2 | — | 50~80 | 7~9 | 8 | Positive1 | |

| 2 | 2~2.5 | 2~3 | — | 90~120 | 8~12 | 8~12 | Positive1 | Butt welding |

| 3 | 2~3 | 3 | — | 150~180 | 8~12 | 8~12 | Positive1 |

Y Butt |

| 4 | 3 | 4 | — | 180~200 | 10~15 | 8~12 | 1~2/1 | |

| 5 | 3~4 | 4 | — | 180~240 | 10~15 | 10~12 | 1~2/1 | |

| 6 | 4 | 5 | — | 240~280 | 16~20 | 14~16 | 1~2/1 | |

| 8 | 4~5 | 5 | 100 | 160~320 | 16~20 | 14~16 | 2/1 | |

| 10 | 4~5 | 5 | 100~150 | 280~340 | 16~20 | 14~16 | 3~4/1~2 | |

| 12 | 4~5 | 5~6 | 150~180 | 300~360 | 18~22 | 16~20 | 3~4/1~2 | |

| 14 | 5~6 | 5~6 | 180~200 | 340~380 | 20~24 | 16~20 | 3~4/1~2 | |

| 16 | 5~6 | 6 | 200~220 | 340~380 | 20~24 | 16~20 | 4~5/1~2 | |

| 18 | 5~6 | 6 | 200~240 | 360~400 | 25~30 | 16~20 | 4~5/1~2 | |

| 20 | 5~6 | 6 | 200~260 | 360~400 | 25~30 | 20~22 | 4~5/1~2 | |

| 16~20 | 5~6 | 6 | 200~260 | 300~380 | 25~30 | 16~20 | 2~3/2~3 | |

| 22~25 | 5~6 | 6~7 | 200~260 | 360~400 | 30~35 | 20~22 | 3~4/3~4 |

If there is any interest in tungsten electrode, please feel free to contact us through the following methods.

Email: sales@chinatungsten.com

Tel.: +86 592 512 9696/+86 592 512 9595

More info>>